Delivering Precision Through

the Finest Materials

At Perfect Tech Group, excellence begins with the materials we use. We carefully select and machine only the highest-grade alloys, steels, and polymers to ensure unmatched strength, precision, and reliability in every CNC component we produce.

Our Material Expertise

Our extensive experience in working with diverse materials allows us to deliver components with precise tolerances and superior performance.

Whether it’s high-strength steels, corrosion-resistant alloys, or lightweight composites, our team understands how to maximize each material’s unique properties to suit specific industrial needs.

TIMELINE HISTORY

Alloy Steels (Grades: EN24, EN19, 4140, 4340)

High-strength steels alloyed with chromium, nickel, and molybdenum for superior hardness, wear resistance, and dimensional stability. Ideal for CNC precision components operating under mechanical stress.

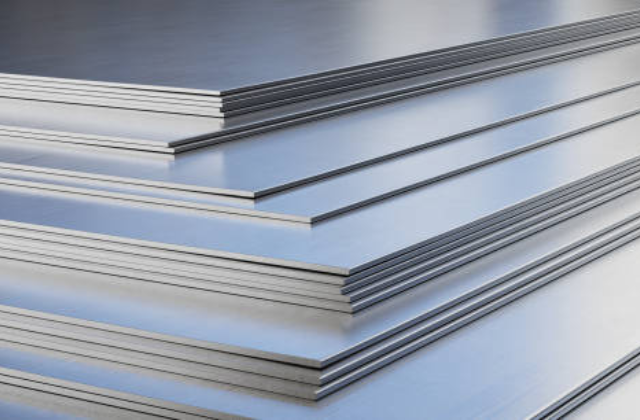

Stainless Steels (Grades: 304, 304L, 316, 316L, 410, 420, 431, Duplex 2205)

Corrosion-resistant steels offering excellent machinability, strength, and surface finish. Perfect for high-performance CNC parts used in corrosive or hygienic environments.

Inconel (Grades: 600, 625, 718,945)

Nickel–chromium-based superalloys designed to maintain exceptional strength and oxidation resistance at elevated temperatures. Used for precision CNC machining in extreme conditions.

Monel (Grades: 400, K500)

Nickel–copper alloys providing superior corrosion resistance in seawater and acidic media. Maintain excellent strength and machinability for demanding CNC applications.

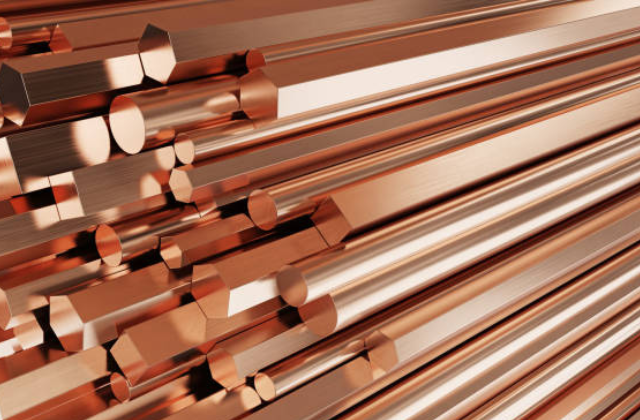

Copper (Grades: C101, C110, ETP, OFHC)

Known for outstanding thermal and electrical conductivity with smooth machining properties and a fine surface finish.

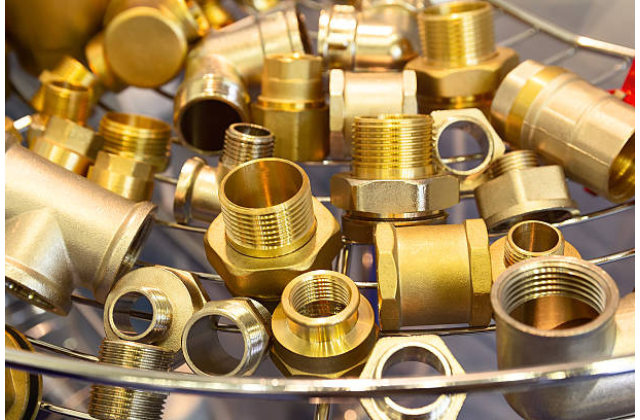

Brass & Bronze (Grades: CZ121, C36000, PB1, LG2)

Highly machinable copper-based alloys offering low friction, good corrosion resistance, and fine surface quality.

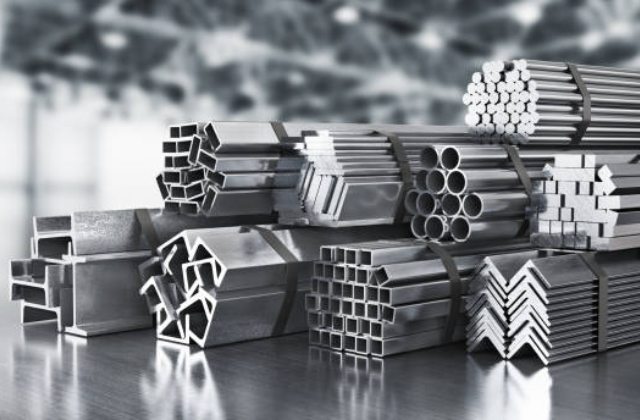

Aluminium (Grades: 6061, 6082, 7021, 7075, 2024, 5052)

Lightweight and corrosion-resistant materials with fast cutting speeds, easy chip removal, and excellent dimensional accuracy in CNC machining.

Aircraft Light Alloys (Grades: Aluminium 7075-T6, Titanium Ti-6Al-4V, Magnesium AZ31B)

Engineered for high strength-to-weight ratio and precision stability. Widely used in aerospace and defense CNC applications.

Engineering Plastics (Grades: Nylon 6, POM-Delrin, PTFE, PEEK, Polycarbonate)

High-performance polymers with strong mechanical and thermal properties. Offer smooth machinability, dimensional stability, and excellent tolerance control.

Carbon Steels (Grades: C20, C45, EN8, EN9, A36)

Versatile steels providing balanced hardness, strength, and machinability for general-purpose CNC components.

Other Materials

Includes titanium, tool steels (H13, D2, O1), and specialized compositions tailored for high-precision CNC manufacturing.